Product Description

The Super EX Durometer is a precision instrument for measuring the hardness of various types of rubbers and plastics. Durable metal cases are rugged enough for a production environment. Super EX handheld durometers are easy to use. The easy operation allows for rapid testing with repeatable results. Super EX models are available in Durometer Types: Shore A Hardness, Shore D Hardness and Asker C Hardness. Select a model number based on the desired testing material.

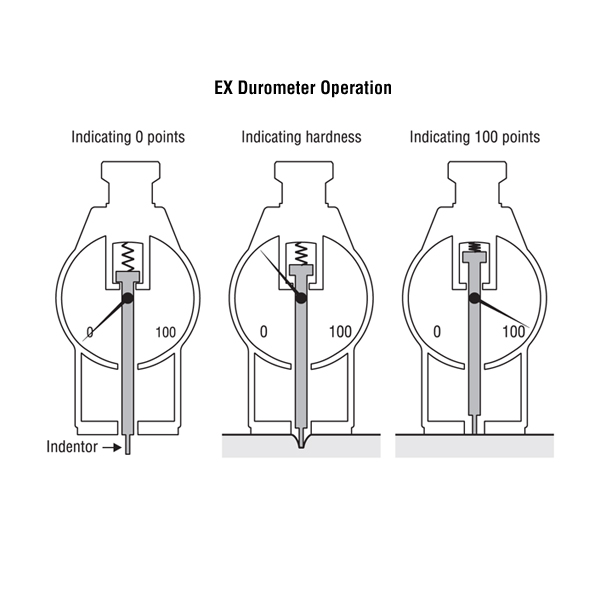

Operation

As the durometer is pressed against the sample, the material resistance force and indentor spring load balance. The depth of the indentor is measured, which provides a measure of the material’s hardness. Values are based upon a 100 point scale (accuracy ±1 point). However, as time elapses the indicator will “creep” back so that a reading taken a few seconds after the indentor makes contact with the sample will be less than the peak reading. Asker durometers offer a peak indicator as an option to more closely monitor the difference between peak and “creep”.

What’s Included with the Durometer?

EX durometers are sold as kits. All new durometer purchases include: durometer, hard plastic carrying case and 3-Point Calibration certificate traceable to NIST.

*Add P to the model number to specify optional peak indicator, for example EXP-A.