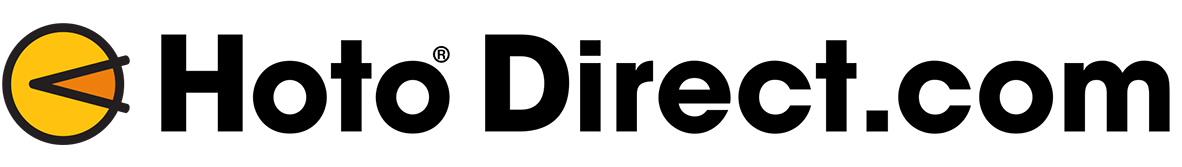

Durometer Scales

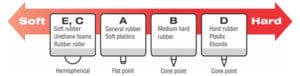

Durometers that measure the hardness of rubber and plastic are available in a range of scales from foam rubber to hard plastic. The Shore A, B, C, D, E scales are technical standards described by ASTM D2240, Standard Test Method for Rubber Property. Asker C scale is described by the Japanese Standards Association, JIS K 7312. A durometer can calibrated to meet these standards and is verified by an calibration certificate traceable to NIST or ISO/IEC 17025 calibration certificate.

Choose a scale that is appropriate for the material you are testing.

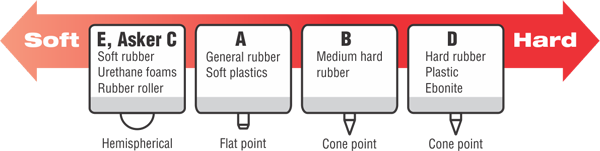

The durometer dial reads from 0 to 100 points.

Readings less than 10 or above 90 should be avoided.

- If more than 90 points in A scale, use D scale.

- If less than 10 points in D scale, use A scale.

- Use other scales to obtain a reading closer to 50 points.

Samples

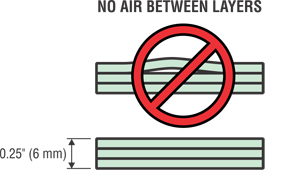

The surface of the sample must be flat, clean and smooth. (Maximum allowable surface roughness is ±0.001″). The sample size must be at least 0.75″ x 1.75″ and thicker than 0.25″ (6 mm).

If the sample is thinner than 0.25″ (6 mm), several layers of the same material can be stacked on top of each other. Make sure there is no air between the layers (Do not glue layers together).

Measurements from samples that do not conform to the above requirements may be taken, but test results should be used only as a reference.

Testing

Take the average of five measurements.

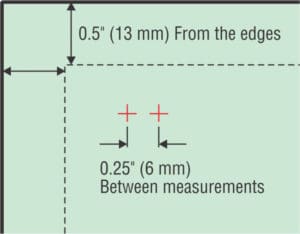

Select different locations on the sample for each measurement, at least 0.25″ away from any previous measurement. Keep your measurements at least 0.5″ from all edges.

Maintain sample temperature at 23° C, ± 2° (73.4° F) for an hour previous to testing.

1. Place the sample on a flat, hard, horizontal surface.

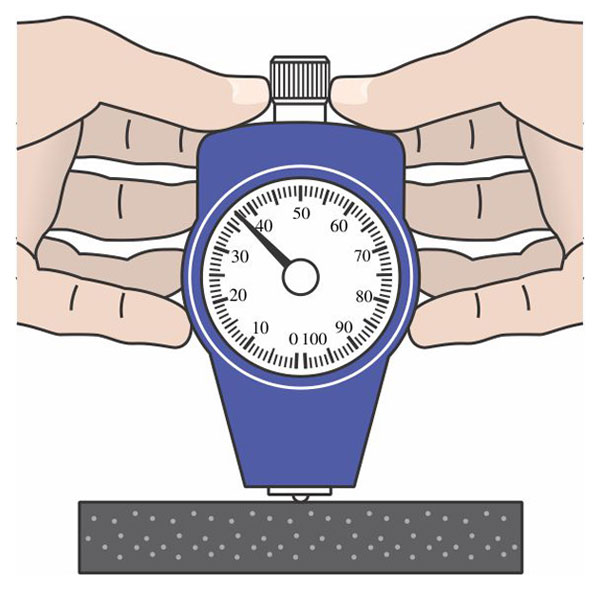

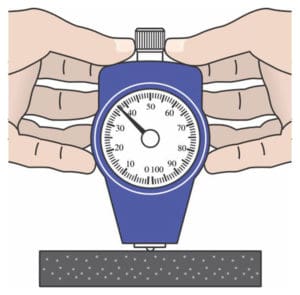

2. Hold the durometer between both hands over the sample so that the indentor touches it.

3. Push down perpendicularly until the presser foot makes firm contact with the sample.

4. Take a reading.

Creep

Measurements may tend to creep back if read at different times after testing. For example, you may get a slightly different reading if you read the result immediately versus 30 seconds later. It is recommended to keep this aspect of measuring consistent.

Storage

If you are using a durometer that has been stored for a while, press the indentor on a surface about 20 times before using it.

To minimize force and speed variables in testing use a constant load stand.